Industry

Naike is established in the industrial vacuum cleaner industry, promoting its sustainable development and progress through various measures such as technological innovation, product research and development, meeting diverse needs, improving services and support, strengthening brand building and market expansion

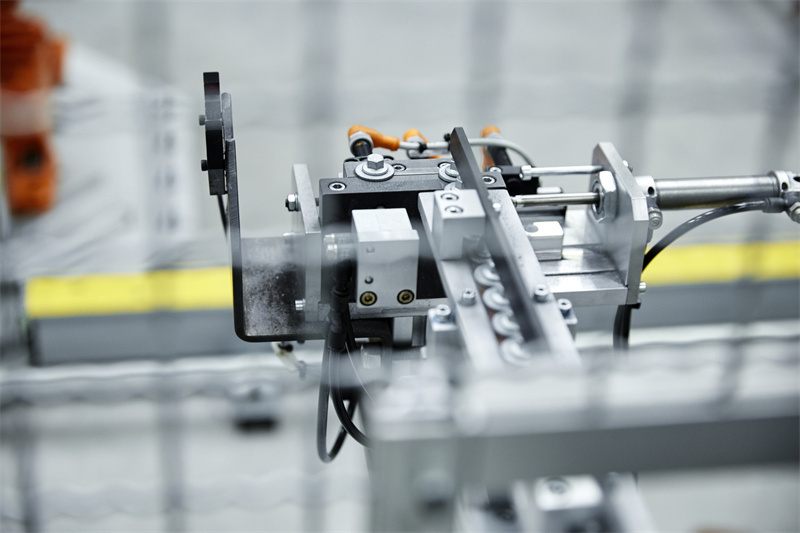

In the manufacturing process, vacuum cleaners are widely used in various production stages, such as

1. Motor manufacturing, etc. By using vacuum cleaners, dust and waste generated during the production process can be effectively removed, ensuring quality and safety.

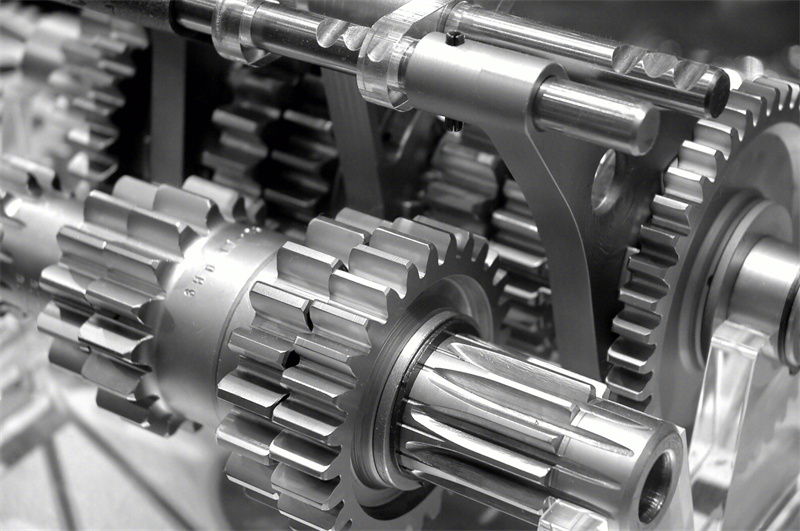

The machining process generates a large amount of dust, chips, oil stains, and other waste. If these wastes are not cleaned up in a timely manner, they can not only pollute the working environment but also damage the machinery, affecting the normal operation and lifespan of the equipment. Additionally, these wastes may pose a threat to workers' health, such as causing respiratory diseases. Therefore, using efficient cleaning equipment—NAICO industrial vacuum cleaners—is crucial for cleanliness and safe production in the machining industry.

Applications of industrial vacuum cleaners:

1. Cutting processing: During the cutting process, a large amount of metal chips and dust is generated. Industrial vacuum cleaners can promptly absorb these wastes, keeping the work area clean and preventing damage to equipment and workers.

2. Grinding processing: Grinding also generates a large amount of dust and debris. Industrial vacuum cleaners can effectively reduce the spread of dust and lower the pollution level of the working environment.

3. Welding processing: Welding generates slag and smoke. Industrial vacuum cleaners can quickly absorb these harmful substances, protecting the health and safety of workers.

4. Cleaning stage: After machining, equipment and work areas need to be cleaned. Industrial vacuum cleaners can absorb wastewater and waste generated during the cleaning process, keeping the work environment tidy.

Advantages of NAICO products:

1. High-efficiency suction: With powerful suction, it can quickly absorb various wastes and dust generated during machining.

2. Filtration system: Equipped with a high-efficiency filtration system that can filter out fine dust particles, preventing secondary pollution.

3. Improved work efficiency: The dust removal method can greatly save time and labor in cleaning up waste, enhancing the production efficiency of machining.

4. Improved working environment: Industrial vacuum cleaners can effectively reduce dust pollution in the working environment, improving the working conditions and health of workers.

The dust removal application of industrial vacuum cleaners in the machining field plays an important role. It not only keeps the working environment clean and tidy, reducing the risk of product contamination, but also protects machinery and extends its lifespan, improving work efficiency. At the same time, it can also improve the working environment and the health of employees, contributing to the sustainable development of enterprises.

recommend products