Industry

Naike is established in the industrial vacuum cleaner industry, promoting its sustainable development and progress through various measures such as technological innovation, product research and development, meeting diverse needs, improving services and support, strengthening brand building and market expansion

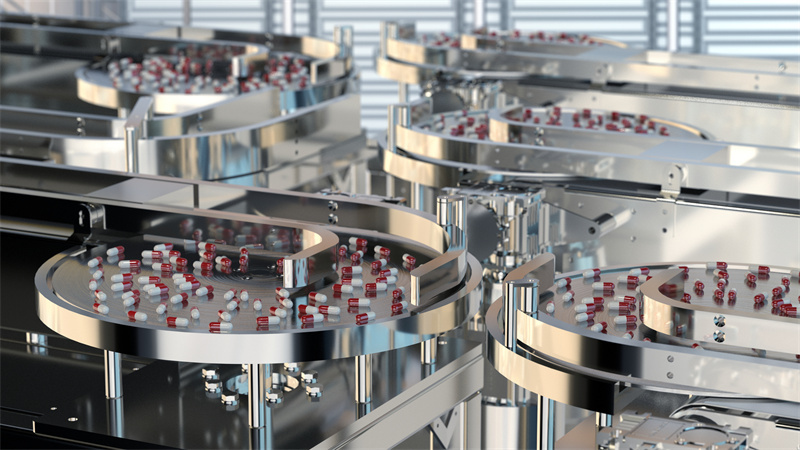

In the pharmaceutical process, vacuum cleaners are widely used in various production stages, such as

1. Tablet dust removal

2. Capsule filling dust removal

3. Capsule polishing and sorting dust removal

4. Micro-pellet and tablet coating dust removal

5. Counting and packaging dust removal

6. Granule and powder packaging dust removal

7. Collection of packaging edge scraps

8. Floor and equipment table cleaning

etc. By using vacuum cleaners, dust and impurities generated during the production process can be effectively removed, ensuring the quality and safety of the drugs.

In the production of pharmaceuticals and food, a large amount of dust and debris is generated when automated equipment is running, requiring dust removal machines to safely, continuously, stably, and efficiently vacuum to avoid residual dust contaminating products and being released into the environment.

NAICO dust removal machines can achieve continuous and efficient dust collection, significantly reducing production losses and improving product yield. They help users greatly reduce costs and increase efficiency while making the production environment safer and more environmentally friendly.

Applications of industrial vacuum cleaners:

1. Remove impurities: Industrial vacuum cleaners can quickly remove dust, debris, and other impurities generated during the pharmaceutical process through powerful suction, preventing them from contaminating the drugs.

2. Maintain production environment: Regular use of industrial vacuum cleaners for cleaning can maintain the cleanliness of the pharmaceutical environment, complying with regulatory requirements such as GMP (Good Manufacturing Practice).

3. Protect production equipment: Vacuum cleaners also help maintain the cleanliness of production equipment, reducing equipment failures and wear caused by the accumulation of impurities, thus extending the equipment's lifespan.

Advantages of NAICO products:

1. High-efficiency filtration: Equipped with a high-efficiency filtration system, capable of capturing fine dust particles, ensuring the cleanliness of the pharmaceutical environment.

2. Explosion-proof design: Some pharmaceutical manufacturing environments may contain flammable and explosive substances, and some NAICO industrial vacuum cleaners have explosion-proof designs to ensure safe use.

3. Easy to clean and maintain: The design of the vacuum cleaner facilitates cleaning and maintenance, reducing downtime and maintenance costs.

Industrial vacuum cleaners play an important role in dust removal work in the pharmaceutical manufacturing field, and their features such as high-efficiency filtration and explosion-proof design make them indispensable cleaning equipment in pharmaceutical factories. By correctly selecting and using industrial vacuum cleaners, production efficiency and product quality can be further improved, ensuring the safety and effectiveness of the drugs.

recommend products