Industry

Naike is established in the industrial vacuum cleaner industry, promoting its sustainable development and progress through various measures such as technological innovation, product research and development, meeting diverse needs, improving services and support, strengthening brand building and market expansion

How to use an industrial vacuum cleaner for grinding machines? What is the price of an industrial vacuum cleaner for grinding machines?

Usage method of industrial vacuum cleaner for grinding machine:

1. When using the industrial vacuum cleaner for the first time, connect the pipeline first to allow dust to be directly sucked in. The pipeline must be sealed tightly; any gaps will affect the suction power.

2. Before the first operation, check if the screws, pipe bundles, and door latch switches are loose.

3. If the suction power is weak, check if there are any blockages in the inlet and outlet pipes.

4. Due to the weight of iron powder, a high-power industrial vacuum cleaner requires a 380V power supply. It is necessary to check if the wires and electrical switches meet the regulations, if the power supply voltage is correct, and if the wiring is correct.

5. To ensure leakage protection, please check if the ground wire is properly connected.

6. Ensure that the machine runs without load for three minutes after starting, and check if the fan's rotation direction is consistent with the inlet of the blower. If there is backflow or weak suction, please swap any two of the three power lines.

7. During use, if you feel a decrease in suction power, please regularly clean the filter to shake off the dust on the filter bag to prevent motor damage. The cleaning frequency depends on the amount of dust.

8. When cleaning dust, the machine must be turned off. Pull out the lower bucket and then dump the dust.

9. Regularly remove dust from the filter. Clean the dust thoroughly to prevent air blockage that reduces suction power, ensuring a flat and tight fit. Generally, the filter should be replaced about once a year.

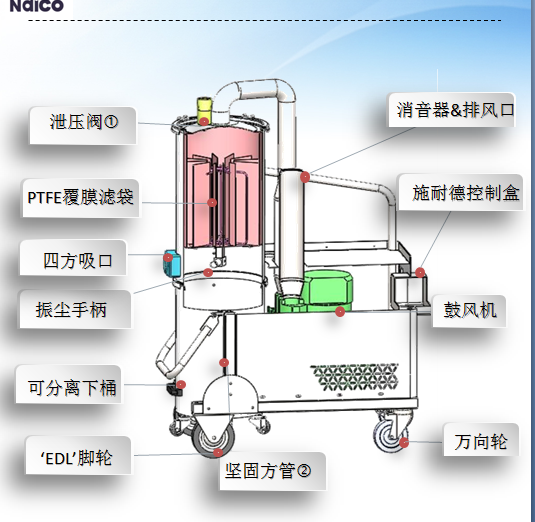

Introduction to the special vacuum cleaner for surface grinding machines

Vacuum fan—— Selected from imported turbine fans, low noise, low vibration, and long lifespan.

Internal filter device—— Uses a polyester fiber filter bucket, environmentally friendly and economical.

Dust collection device—— Uses a stainless steel bucket for easy cleaning and sealed self-settling dust.

External pipeline—— Uses specially matched corrugated pipes to connect the grinding machine's dust hood.