Industry

Naike is established in the industrial vacuum cleaner industry, promoting its sustainable development and progress through various measures such as technological innovation, product research and development, meeting diverse needs, improving services and support, strengthening brand building and market expansion

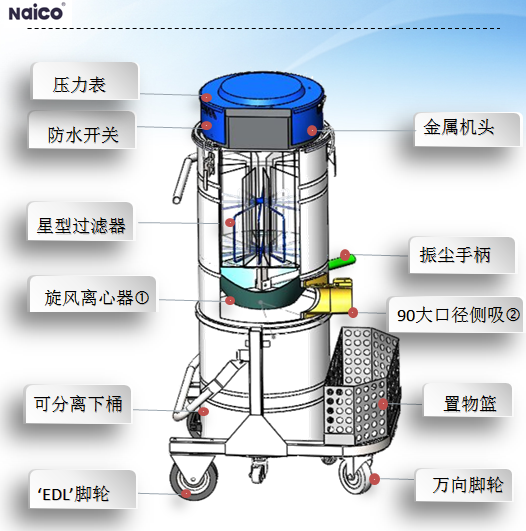

The working principle of a vacuum industrial cleaner for sucking powder.

Working principle of vacuum industrial vacuum cleaners:

The vacuum industrial vacuum cleaner creates a vacuum inside the barrel through a dust suction motor, causing the negative pressure to rise rapidly. The high negative pressure allows air to flow quickly through the intake port into the barrel. The flowing air carries solid particles that need to be collected and processed into the barrel through the dust suction brush and suction pipe. The filter bag connects with the intake port, and solids adhere to the inner surface of the filter bag. The initially filtered air passes through the gaps in the filter bag and undergoes secondary filtration through the filter element, allowing the air to meet discharge standards. The filtered air then enters the exhaust duct through the fan's exhaust port, ultimately being returned to the workshop to reduce energy loss, especially thermal energy loss. The higher the negative pressure, the stronger the suction. The wider the suction port, the greater the flow, which correspondingly reduces the negative pressure and suction. By selecting the appropriate model, the negative pressure can be maintained within a constant range to adapt to the suction and processing of different materials.

Vacuum industrial vacuum cleaners can collect various solid and liquid waste:

Vacuum industrial vacuum cleaners have almost no requirements for the materials being sucked. Waste materials of various types and shapes can be collected. The objects that can be sucked include various metals, non-metals, oil, water, and other particulate waste and liquids, as well as some expensive catalysts in the chemical industry. They can also absorb toxic and harmful gases for stabilization, especially by replacing different filtering media, such as filter elements and filter bags, which can absorb solid particles larger than 0.3 microns with an accuracy of up to 99%. This makes them suitable for industries such as fine chemicals and precision machinery.

Vacuum industrial vacuum cleaners can work for long periods, suitable for industrial needs:

Compared to other vacuum cleaners, vacuum industrial vacuum cleaners have advantages such as continuous use for 24 hours, strong suction, large dust storage capacity, long service life, and high-temperature resistance. The machine casing and dustbin are made of steel or iron plates that meet thickness standards, effectively protecting the motor from damage. Factory workers can take breaks and rotate in shifts, but the machine does not stop working, which particularly requires a vacuum industrial vacuum cleaner that can operate continuously for 24 hours to support dust collection.