Industry

Naike is established in the industrial vacuum cleaner industry, promoting its sustainable development and progress through various measures such as technological innovation, product research and development, meeting diverse needs, improving services and support, strengthening brand building and market expansion

What are some brands of industrial vacuum cleaners with good quality?

What are some brands of industrial vacuum cleaners with good quality?

Industrial vacuum cleaners look the same on the outside, so how can we know which brand has good quality? Here are a few points summarized by the editor:

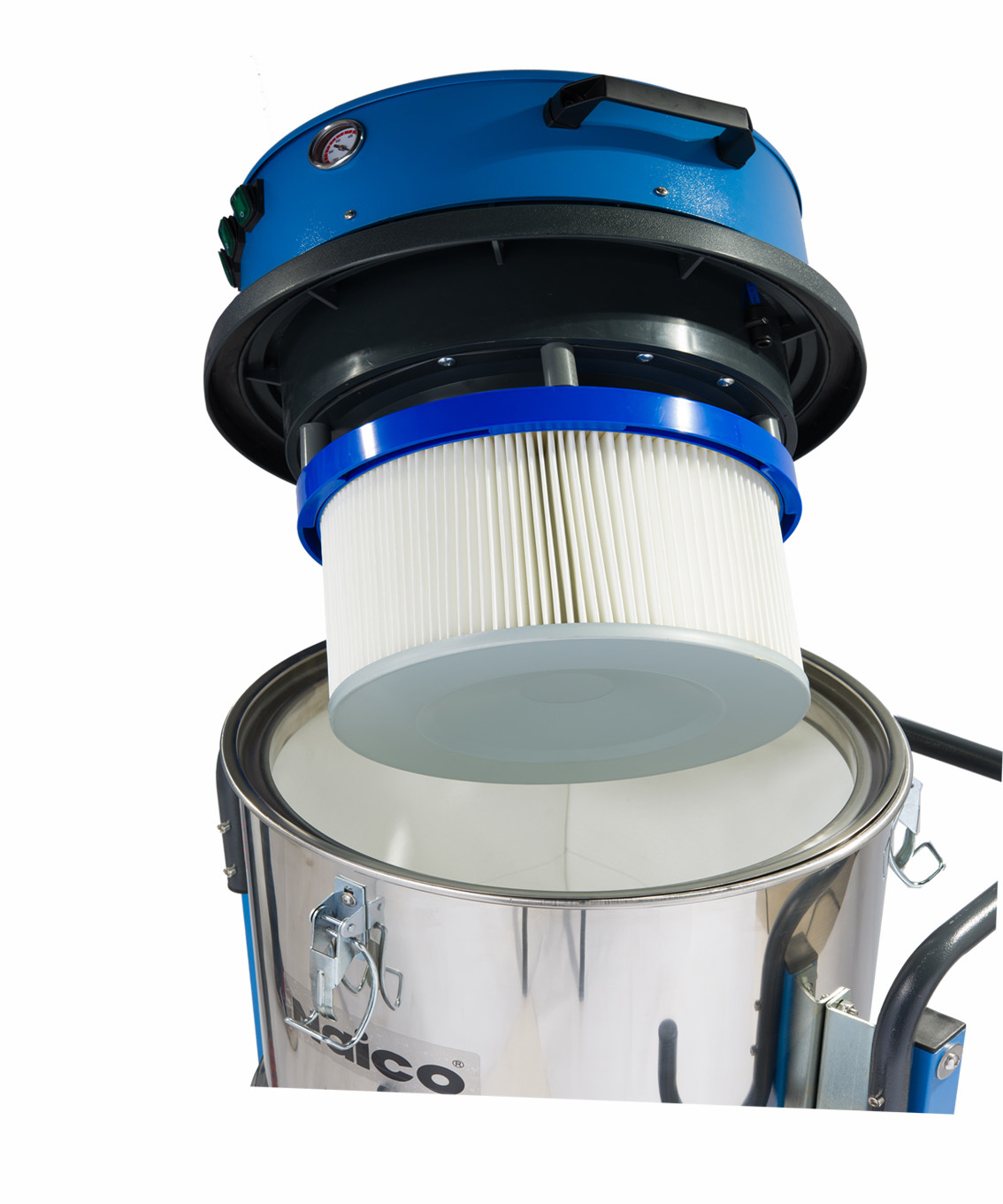

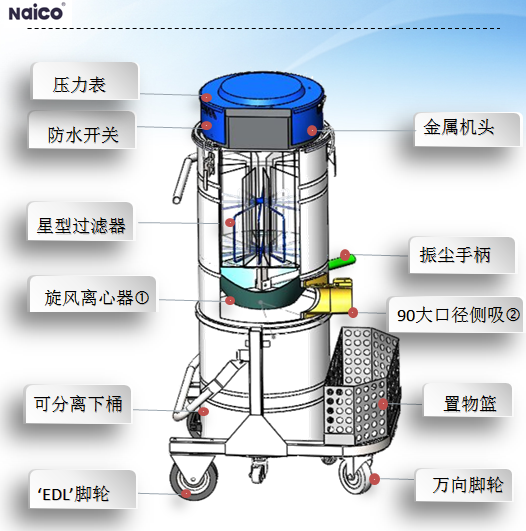

1. From the appearance, a metal body is sturdy and durable, suitable for multiple environments, with good heat dissipation. Plastic ones may not meet the requirements in some environments, as they can easily deform at high temperatures, and their sealing is not as perfect as that of metal.

2. At the same price level, look at the filtering system of a machine, as it is like the brain of a person. The size of the filtering area and the filtering material determine the quality of a machine.

3. The choice of motor for industrial vacuum cleaners is also crucial. Some domestic motors do not meet the standards for industrial vacuum cleaners, and using them forcibly can lead to a short lifespan of the machine.

4. The core of the machine is the coordinated operation of various systems. Companies with a long history have their own complete teams and production lines, which can integrate various components well.

Industrial vacuum cleaners are specialized dust collection devices used in industrial environments to collect industrial dust, oil, water, harmful gases, etc. They can be used for daily cleaning in industrial environments and can also be placed on-site during the production process for collection.

Generally speaking, industrial vacuum cleaners are different from those used for commercial cleaning. Industrial cleaning uses 220V and 380V voltage, but the vacuum filtering box is larger, the appearance is sturdier (usually metal structure), and the filtering area is larger.

The motors used are more durable or have special purposes (such as heat resistance, oil resistance, corrosion resistance, etc.). Industrial production requires continuous use, so three-phase motors are selected. If you choose an industrial vacuum cleaner, first determine the usage scenario and frequency before deciding on the type of industrial vacuum cleaner.

Determine the type of industrial vacuum cleaner based on the usage scenario and frequency.