Industry

Naike is established in the industrial vacuum cleaner industry, promoting its sustainable development and progress through various measures such as technological innovation, product research and development, meeting diverse needs, improving services and support, strengthening brand building and market expansion

Standards and治理 methods for environmental dust workshop detection

Coal mining production has its own particularities compared to other enterprises. According to the "Coal Mine Safety Regulations" issued by the National Administration of Coal Mine Safety, the main occupational hazard factors in coal mining production can include the following categories: 1. Dust. The most significant harmful factor at coal mining production sites and occupational hazards; 2. Harmful gases such as carbon monoxide, carbon dioxide, sulfur dioxide, and nitrogen oxides underground; 3. Production-related toxic substances such as trinitrotoluene, lead, benzene, and mercury; 4. Physical factors such as noise, vibration, high temperature, and high humidity. The harmful factors that can be detected on-site are the first, second, and fourth categories, while the detection of the third category of production-related toxic substances generally requires large specialized analytical instruments and is usually not conducted on-site.

Determination of Dust

Dust generated during the production process that can remain suspended in the air for a long time is referred to as production dust. Production dust is an occupational harmful substance that pollutes the working environment and affects workers' health. Long-term inhalation of dust during the production process can harm human health, and prolonged inhalation of certain production dust can lead to systemic diseases primarily characterized by pulmonary tissue fibrosis, such as pneumoconiosis (silicosis). For example, free SiO2 can lead to silicosis, and asbestos dust can cause asbestosis.

During the production operations in coal mines, such as mechanized mining, comprehensive mining, blasting, retreat mining, anchor spraying, transportation, and coal selection, a large amount of dust can be generated. Respirable dust is a part of the dust produced during coal production. Workers operating in environments with high coal dust concentrations for extended periods can inhale respirable coal dust, leading to pneumoconiosis, which severely endangers the health of coal miners. To evaluate the hazards of dust in the workplace, strengthen the scientific management of dust prevention measures, and protect workers' health, it is necessary to monitor the dust in the air at the work site. The monitoring of dust in the air at the work site includes the following three types: total dust concentration in the workplace, individual and fixed-point respirable dust concentration measurement, and measurement of free silica content in dust, as well as dust dispersion measurement.

1. Physicochemical Properties and Health Significance of Production Dust

(1) Dust Concentration

The greater the dust concentration, the more severe the harm to the human body. Dust containing more than 10% free silica has a greater impact on the development of lung tissue lesions than dust with less than 10% content.

(2) Dust Dispersion

Dust dispersion refers to the degree to which a substance is crushed, expressed as the percentage composition of dust particles of different sizes. The higher the dust dispersion, the more stable the aerosol system formed, the longer it remains suspended in the air, and the greater the chance of being inhaled by the human body; the higher the dust dispersion, the larger the specific surface area, making it easier to participate in physicochemical reactions, thus posing greater harm to the human body.

(3) Chemical Composition of Dust

Dust with different chemical compositions has different effects and degrees of harm to the human body. For example, asbestos dust can cause asbestosis and mesothelioma, while cotton dust can lead to byssinosis; dust containing free silica can cause pneumoconiosis.

(4) Solubility, Charge, Shape and Hardness, Explosiveness of Dust

2. Determination of Dust Concentration

(1) Overview

Dust concentration refers to the amount of dust contained in a unit volume of air. There are two methods for expressing dust concentration: gravimetric method and counting method, represented by mass concentration (mg/m3) and number concentration (particles/cm3), respectively. The health standards in our country use the mass concentration method for representation.

In coal mining workplaces, the main dust concentrations measured are total dust and individual respirable dust. The former is sampled during the production process, with a short sampling time (15-30 minutes) and a large flow rate, allowing for the measurement of the instantaneous concentration of dust in the air. The latter uses continuous sampling, meaning sampling continuously throughout the entire work shift, using individual samplers for continuous sampling. This has a longer duration and a smaller flow rate (2L/min), allowing for the measurement of the average concentration of dust that can be inhaled by workers over the entire work period. Generally, filter membranes and dust samplers are used for sampling.

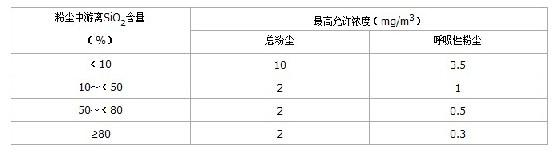

In the standards, the permissible dust concentration in coal mining workplaces is specified with total dust standards and respirable dust standards (see Table 1). According to the permissible concentration regulations, total dust concentration measurement methods and respirable dust concentration measurement methods should be used.

Table 1 Dust Concentration Standards in Workplace Air

Coal dust: coal dust in the workplace air with free silica content less than 10%. (GB16248-1996 Health Standards for Respirable Coal Dust in Workplaces)

There are many methods and standards for dust determination, such as national standards GB5748-1985 "Methods for Determining Dust in Workplace Air", GB5817-1986 "Classification of Production Dust Hazard Levels", GB16248-1996 "Health Standards for Coal Dust in Workplace Air", GB16225-1996 "Health Standards for Respirable Dust in Workshop Air", and departmental standards from the Ministry of Labor, Ministry of Coal, etc., such as LD39-1992 "Management Standards for Respirable Coal Dust Exposure Concentration in Workplaces", LD38-1992 "Methods for Determining Individual Respirable Dust in Mines", MT79-1984 "Methods for Determining Dust Concentration and Dispersion", etc.

(2) Determination of Total Dust - Filter Membrane Weight Method

1. Principle: Collect a certain volume of dust-laden air, retaining the dust on a filter membrane of known mass, and calculate the concentration of dust in the air C (mg/m3) based on the difference in mass of the filter membrane before and after sampling and the volume of air sampled.

2. Equipment

1) Dust sampler: Product inspection qualified. Explosion-proof type. (MT162-1995 General Technical Conditions for Dust Samplers)

2) Filter membrane: Polyvinyl chloride fiber filter membrane (Characteristics: high dust retention rate >99%, low resistance, lightweight, strong charge and water retention). Diameter 40mm or 75mm. If unsuitable (not heat-resistant), can switch to fiberglass filter membrane.

3) Sampling head:

Used to fix the filter membrane. Composed of a top cover, filter membrane clamp, and base. The filter membrane clamp consists of a clamp cover, clamp ring, and clamp seat (see Figure 1). It ensures close contact and guarantees airtightness.

Flow meter: commonly used 15-40L/min, graduation value 0.1L/min, maximum flow 80L/min. Commonly used rotor flow meter.

Timer: stopwatch or a timer equivalent to a stopwatch. The timer on the sampler should be synchronized with the sampling switch.

Vacuum pump: the sampler consists of a pump body, micro motor, and battery. It can operate continuously for more than 120 minutes.

Balance: analytical balance with a graduation value (sensitivity) of no less than 0.0001g, regularly calibrated.

Dryer: contains color-changing silica gel.

3. Measurement Procedure

Preparation of the filter membrane: weigh the filter membrane → place it in the filter membrane clamp → number it → store it for later use.

Sampling: select the sampling location based on the sampling purpose (Appendix: factory, underground mine tunnel project, open-pit mine, etc.). Tighten the filter membrane clamp into the sampling head. Sampling flow rate: maintain a constant 20L/min. The sampling duration should generally not be less than 10 minutes. After sampling, turn off the sampler, remove the filter membrane clamp, place it in the storage box, and bring it back to the laboratory for analysis, recording the environmental conditions and circumstances of the on-site sampling.

Bag dust removal equipment uses textile filter cloth or non-woven felt to make filter bags, utilizing the filtering effect of fiber fabric to filter dust-laden gas. When dust-laden gas enters the bag filter, larger and heavier dust particles settle down due to gravity and fall into the ash hopper. The gas containing finer dust is filtered through the filter material, where the dust is retained, purifying the gas. Generally, the dust removal efficiency of new filter materials is not high enough. After a period of use, due to effects such as sieving, collision, retention, diffusion, and static electricity, a layer of dust accumulates on the surface of the filter bag, known as the initial layer. In subsequent movements, the initial layer becomes the main filtering layer of the filter material. Relying on the effect of the initial layer, filter materials with larger pores can also achieve high filtering efficiency. As dust accumulates on the surface of the filter material, the efficiency and resistance of the bag dust removal increase accordingly. When the pressure difference on both sides of the filter material is large, some fine dust particles that have adhered to the filter material may be squeezed past, reducing dust removal efficiency. Additionally, excessive resistance of the filter material can significantly decrease the airflow of the dust removal system. Therefore, when the resistance of the bag dust collector reaches a certain value, it is necessary to clean the dust in a timely manner. During dust cleaning, the initial layer should not be damaged to avoid a decrease in efficiency. Due to the differences in efficiency and resistance between the two different filtering stages, the stability of the bag dust removal effect is relatively poor.

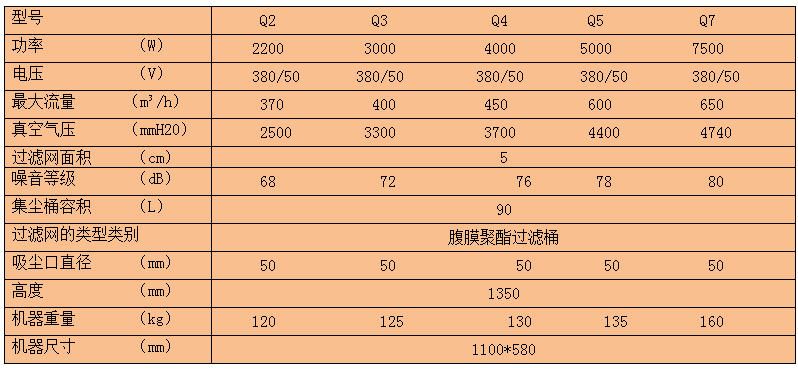

Bag dust removal equipment parameters

Biological nano film dust suppression technology, also known as biological nano dust suppression technology, is a new industrial dust control method that surpasses traditional technologies such as bag dust removal, closed dust removal, and spray dust removal. It has various applications overseas. In recent years, this technology has also begun to be gradually applied in industrial and mining enterprises in many provinces and cities in China. Biological nano film dust suppression technology suppresses dust generation at the source by generating precisely proportioned biological nano films through a biological nano film dust suppression machine, which are sprayed onto materials. Through the adsorption of the biological nano film, small dust particles aggregate into larger particles, increasing their weight so that they cannot disperse into the air and form dust. This technology can effectively control both organized and unorganized dust, achieving a dust removal rate of over 95%, with stable effects. The biological nano film formulation does not affect the quality of the finished product and does not cause secondary pollution to the environment. In addition, biological nano film dust suppression technology can effectively prevent and control PM2.5 and PM10 fine particulate pollution.

Spray dust removal is a traditional wet dust removal method in the field of dust removal technology. Traditional spray dust removal uses mist as the medium for dust removal, forming water mist through traditional spray nozzles to envelop materials and achieve dust removal effects. Spray dust removal is widely used in industrial fields such as mines, quarries, and steel mills, and has a certain dust removal effect. However, the drawbacks of this technology include wetting the materials, affecting the quality of the finished product, and causing the wet materials to stick, which can lead to significant wear on production equipment. Additionally, it can cause water pollution, requiring wastewater treatment.

On the surface, spray dust removal shows quick results and low costs, but considering the overall usage costs, management costs, and environmental damage, the price of this dust removal method is quite high. In recent years, traditional spray dust removal has also begun to be gradually replaced by cloud mist dust suppression technology.

Cloud mist dust suppression technology generates ultra-fine mist particles ranging from 1μm to 100μm through high-pressure ionization and ultrasonic atomization technologies. The ultra-fine mist particles are dense and can significantly increase the contact area with dust particles. The cloud mist particles collide and coalesce with dust particles, forming aggregates that continuously grow larger and heavier until they eventually settle naturally, achieving the goal of eliminating dust. The cloud mist particles produced by cloud mist dust suppression technology have 30%-40% of their particle size below 2.5μm, showing significant effects in preventing fine particulate pollution in the atmosphere. Due to the extremely fine nature of the cloud mist particles, they have good adsorption properties for dust, greatly improving dust removal efficiency, and they do not wet the materials, avoiding the drawbacks of traditional spray technology.